Page 144 - Manual Oficina Polaris RZR 570 13-18

P. 144

ENGINE / COOLING SYSTEM

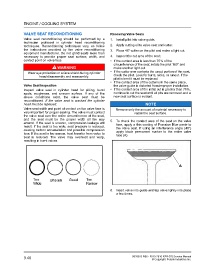

VALVE SEAT RECONDITIONING Renewing Valve Seats

Valve seat reconditioning should be performed by a 1. Install pilot into valve guide.

technician proficient in cylinder head reconditioning

techniques. Reconditioning techniques vary, so follow 2. Apply cutting oil to valve seat and cutter.

the instructions provided by the valve reconditioning 3. Place 46° cutter on the pilot and make a light cut.

equipment manufacturer. Do not grind seats more than

necessary to provide proper seat surface, width, and 4. Inspect the cut area of the seat:

contact point on valve face. • If the contact area is less than 75% of the

circumference of the seat, rotate the pilot 180° and

WARNING make another light cut.

• If the cutter now contacts the uncut portion of the seat,

Wear eye protection or a face shield during cylinder

head disassembly and reassembly. check the pilot. Look for burrs, nicks, or runout. If the

pilot is bent it must be replaced.

• If the contact area of the cutter is in the same place,

Valve Seat Inspection the valve guide is distorted from improper installation.

Inspect valve seat in cylinder head for pitting, burnt • If the contact area of the initial cut is greater than 75%,

spots, roughness, and uneven surface. If any of the continue to cut the seat until all pits are removed and a

above conditions exist, the valve seat must be new seat surface is evident.

reconditioned. If the valve seat is cracked the cylinder

head must be replaced. NOTE

Valve seat width and point of contact on the valve face is Remove only the amount of material necessary to

very important for proper sealing. The valve must contact repair the seat surface.

the valve seat over the entire circumference of the seat,

and the seat must be the proper width all the way

around. If the seat is uneven, compression leakage will 5. To check the contact area of the seat on the valve

result. If the seat is too wide, seat pressure is reduced, face, apply a thin coating of Prussian Blue paste to

causing carbon accumulation and possible compression the valve seat. If using an interference angle (46°)

apply black permanent marker to the entire valve

loss. If the seat is too narrow, heat transfer from valve to face (A).

seat is reduced. The valve may overheat and warp,

resulting in burnt valves.

6. Insert valve into guide and tap valve lightly into place

a few times.

3.46 9926813 R06 - 2013-2016 RZR 570 Service Manual

© Copyright Polaris Industries Inc.